The following are testing approaches used to ensure the trustworthiness and factor of protection in the pressure vessel.

The variable of security is often included in these formulation also, in the situation of the ASME BPVC this expression is included in the material strain worth when resolving for pressure or thickness. Winding angle of carbon fibre vessels[edit]

Composite pressure vessels are frequently filament wound rovings inside of a thermosetting polymer matrix. The mandrel could possibly be removable just after cure, or could continue being a Section of the finished product, frequently giving a far more trustworthy gas or liquid-limited liner, or improved chemical resistance to your intended contents than the resin matrix. Metallic inserts could possibly be provided for attaching threaded equipment, for instance valves and pipes.

Learn More Beer, Beer, and a lot more Beer! From compressors to nitrogen turbines to blowers, we've got The perfect suite of items that assistance your brewery brew the proper pint at the bottom cost of ownership.

We will let you optimize your compressed air installation. Speak to us for your quotation or to speak to a Kaeser consultant about our products.

In many electricity crops and their assembly strains, compressed air plays an important job in avoiding contamination of food items and beverage containers. Here are a few samples of how vaporized h2o can influence products and products in numerous industries:

The composite material might be wound close to a steel liner, forming a composite overwrapped pressure vessel.

Desiccant dryers count on desiccants, a dry substance — generally out there to be a powder or small beads or read more pellets — lined in surface area pores that appeal to and remove h2o by way of a procedure called physisorption.

It then requires cylindrical pressure vessels to acquire thicker walls to resist equal quantities of pressure than a spherical vessel.

Humid function environments: Superior humidity levels have all the things to try and do with how powerful an air compressor is, no matter its size or age. Retaining the correct humidity in particular States is tough due to persistently scorching temperatures professional.

Pressure vessel dangers are dealt with in particular specifications for general market, maritime, and development. This part highlights OSHA benchmarks and files related to pressure vessels.

We use each aspect of our knowledge and expertise to ensure maximum dependability of one's compressed air supply: distant diagnostics, 24/seven unexpected emergency availability and Superior components logistics infrastructure.

A typically used entry hole form is elliptical, which allows the closure being passed with the opening, and rotated into your Doing work position, and is also held set up by a bar on the surface, secured by a central bolt. The inner pressure prevents it from currently being inadvertently opened under load. Employs[edit]

Production: Manufacturing services use dry compressed air for device products and maintenance, and any undesired dampness could injury higher-carrying out units and put on parts down.

Haley Joel Osment Then & Now!

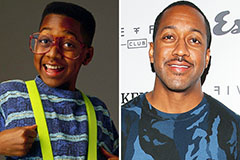

Haley Joel Osment Then & Now! Jaleel White Then & Now!

Jaleel White Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Kenan Thompson Then & Now!

Kenan Thompson Then & Now! Bill Murray Then & Now!

Bill Murray Then & Now!